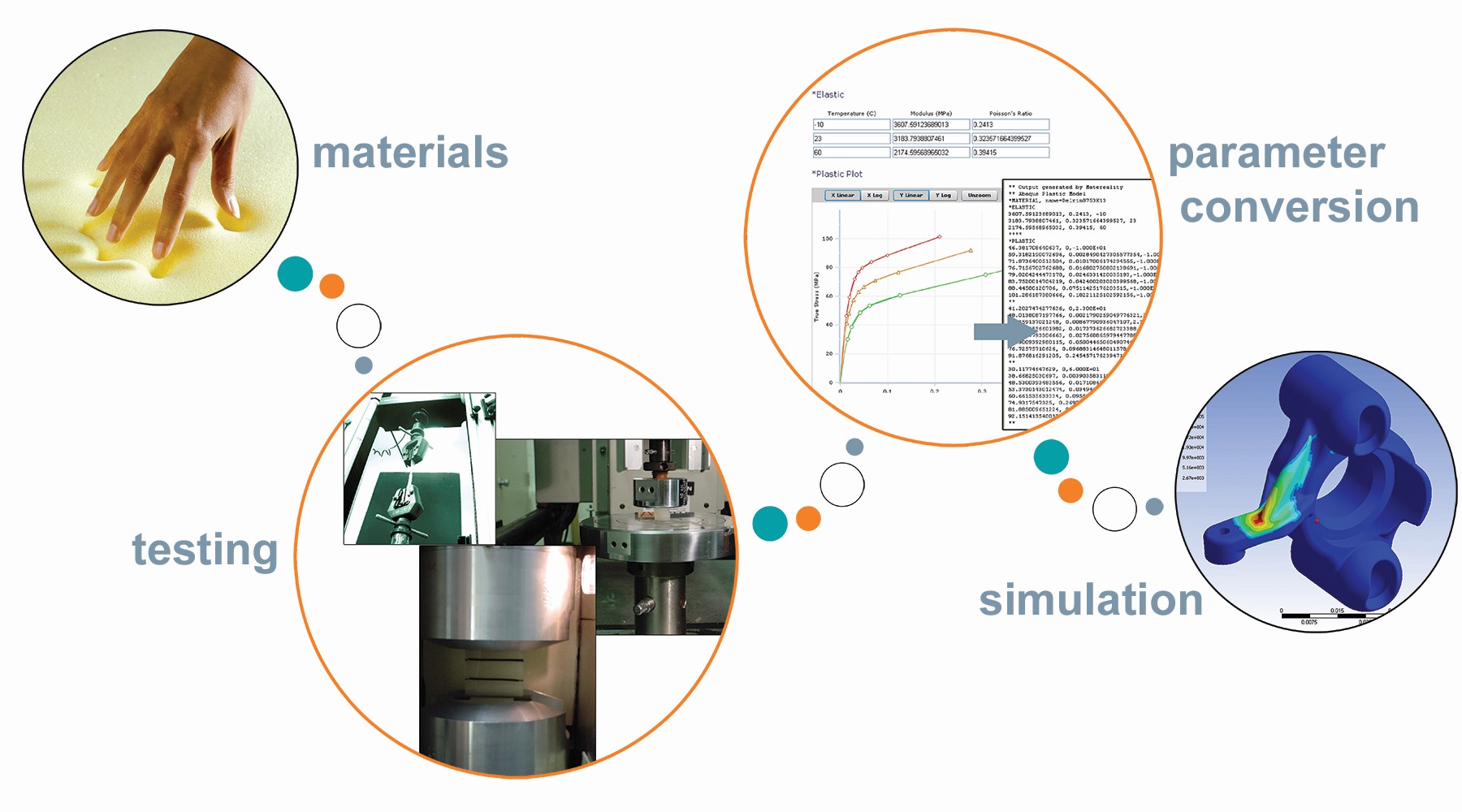

Materials Testing for CAE Simulation

Structural analysis (FEA), injection-mold analysis, computational fluid dynamics (CFD), and other CAE programs rely on precise representations of material behavior.

Applus+ materials testing experts have streamlined material modeling for CAE into an efficient process to consistently deliver accurate results.

TestPaks – material parameters for CAE

TestPaks are testing suites designed to create CAE-ready material models. Select the right material models, generate the right data, and get it into your simulations, backed up by a team of industry experts every step of the way.

- Includes all the measurements and model fittings needed for your simulation.

- Cost-effective and easy to order - they are available for most common material models.

- A single property generation process for each material model.

- CAE-ready material files are deposited into your CAE Materials library in Matereality.

Experts in testing for simulation

- Comprehensive knowledge of materials: plastics, metals, rubber, foam, composites, adhesives.

- Clear focus on characterizing material properties, specifically on properties needed for new product design.

- CAE-neutral– we are partnered with all major FEA and process simulation software providers.

- Support of new processes being developed in product manufacturing (3D design).

Process Simulations and New Manufacturing Processes

Plastics injection molding simulations require highly complex, non-linear data inputs, including viscosity, thermal properties, PVT, and mechanical properties.

For new processes such as 3D printing or additive manufacturing, our extensive experience with thermal, rheological, and mechanical characterizations helps our clients design and build reliable parts directly from CAD.

Blow molding and thermoforming simulations utilize extensional and viscoelastic material data inputs.

Our laboratories generate data and analysis-ready material files for all major process simulations used in the industry today.

Crash & drop test simulation data

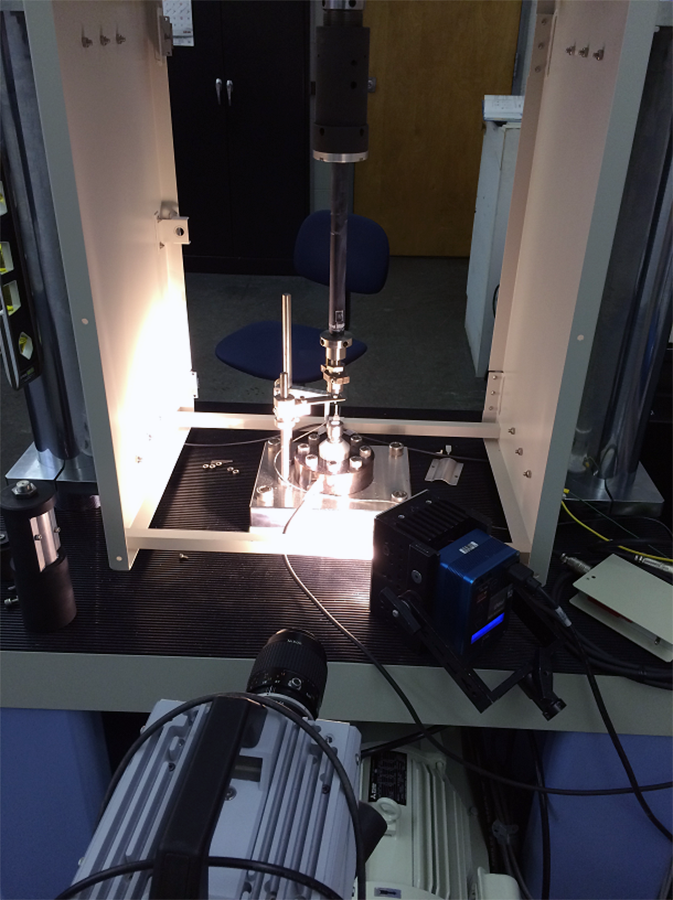

Simulation of crash and impact phenomena require rate-dependent properties. These are usually stress-strain curves measured over several decades of strain rate. We provide rate-dependent data and parameter conversion for metals, plastics, rubbers, foams, and composites, including more complex experiments to model yield surfaces, plasticity, and failure.

We also offer very high speed testing (up to 1000/s), which is used for appliance drop tests and crash and airbag deployment simulations.

Hyperelastic modeling of rubber

A hyperelastic material can be thought of as any type of rubbery material that exhibits large recoverable strains up to failure. Because such material is highly deformable and its Poisson’s ratio is nearly 0.5, deforming the material by stretching, compressing, or twisting in one direction results in a large deformation response in other directions. This coupling means that the material behavior cannot be predicted using properties generated in only one deformation mode. We support all commonly used finite-element simulations with multi-mode test data, along with fitting to mathematical models such as the Mooney- Rivlin or Ogden equations.

Elastomeric and crushable foams

Foams are complex materials, the behavior of which can be tailored to the application purpose. The most common mode of deformation is by compression. Foams are usually not strong in tension or shear and are rarely intentionally subjected to deformation in these modes. Our support for foam modeling includes testing for factors such as rate dependency, hyperbolic extrapolation for impact simulation and hyper-viscoelasticity.

Creep, fatigue, long-term behavior

The modeling of time-based phenomena is gaining widespread use in industry, as analysts try to predict the long-term behavior of products. While classical creep experiments are most common for this kind of analysis, viscoelastic modeling provides predictive advantages at small strains for certain types of materials. Creep rupture experiments are useful to gauge time-dependent failure, while cyclic fatigue data is vital to ensure that products do not fail in the field.

CAETestBench – Validate your CAE simulations

CAETestBench is a process where we validate your simulation against a physical part that has been created and tested using a rigid protocol, which can be accurately replicated in your solver.

With this, it is possible to probe the accuracy of the simulation to quantify its ability to replicate real-life simulations. The deformations range from simple tensile modes to more complex, multi-axial modes, impact, and failure.